Click on the units below to view more information about the refining process.

Distillation Towers

Refining begins in the crude distillation towers. The crude distillation towers provide the first refining step by separating raw crude oil into products with different boiling ranges. These petroleum fractions are further processed in downstream units.

Vacuum Distillation

The Trainer Refinery has three vacuum stills. Along with the crude distillation towers, the vacuum stills provide the first step in the refining process by separating raw crude oil into products with different boiling ranges.

Naphtha Hydrotreating

- Primarily processes straight run naphtha from the crude stills to remove impurities such as sulfur, nitrogen, oxygen, and trace metals.

- Single stage reactor that operates in a hydrogen rich atmosphere.

- Products from the unit include heavy naphtha (reformer feed) and light naphtha for blending into gasoline.

Fluid Catalytic Cracking

- Converts heavy gas oil and resid into LPG, gasoline, diesel feedstock, and fuel oil blending stocks.

- Feeds downstream value chain of Alkylation.

- Catalytic process operated at low pressure and high temperature.

Isocracker

- The primary purpose of the Isocracker is to convert a blend of atmospheric gas oil and light vacuum gas oil into LPG, gasoline, reformer feedstock, and ultra low sulfur diesel.

- The Isocracker is a two-stage reaction plant followed with a tail-end distillation.

- Catalytic process operated at high pressure in a hydrogen rich atmosphere.

Catalytic Reforming

- Upgrades low octane naphtha into high octane gasoline blendstocks.

- The upgrading results from rearranging or “reforming” the gasoline molecules in contact with a platinum catalyst.

- Also produces hydrogen used in the naphtha and distillate hydrotreaters.

Diesel Hydrotreating Desulferization

- Converts sulfur-containing compounds so that the product meets ultra low sulfur diesel (road diesel) specifications.

- The diesel reactors contain fixed beds of catalyst that operate in a hydrogen rich atmosphere.

- Monroe converted a vacuum gas oil hydrotreater to a second distillate hydrotreater (D-2) in August 2013.

Jet Fuel Treating

- Straight run kerosene feed comes from the 543 and 544 Crude Units.

- To dry the steam stripped kerosene, a coalescer and salt drying are used.

- The dried kerosene is then routed to storage through the clay filters designed to remove contaminants such as scale and water.

Alkylation

- Uses olefin feed stocks of propylene and butylene to react with isobutane to produce Alkylate, a high octane gasoline blend stock.

- Propane and butane are also products from the Alky Unit.

Gasoline Blending

- Designed to blend as many as eight gasoline components in preselected proportions or “recipes” in order to achieve the desired octane number.

- Finished blended product is then transferred to on-site tankage, a product barge, or remote tankage at the Chelsea tank farm through a dedicated pipeline.

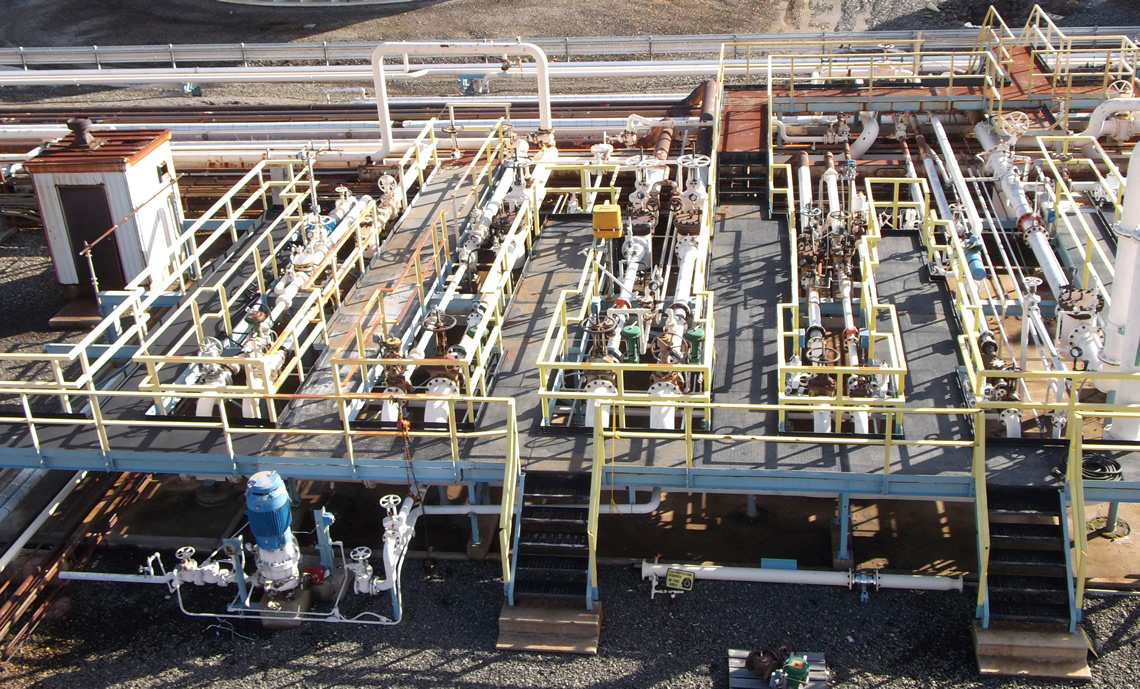

Crude Oil Storage

The Trainer Refinery has two main storage areas – the North and South tank farms.

The North tank farm has approximately 29 storage tanks with a total storage capacity of about 1.0 million barrels. Most tanks are atmospheric storage tanks including cone roof, covered, and external floating roof tanks.

The South tank farm has approximately 60 storage tanks with a total storage capacity of about 3.5 million barrels. All LPGs stored in the South tank farm, including propane, butane, and isobutane are stored in spheres designed for higher pressurization.

Ultra Low Sulfer Gasoline Hydrotreater

- Gas treatment at this stage is focused on further reducing the sulfur content of cracked naphtha to parts-per-million levels through hydrodesulphurization.

- Making these sulfur reductions aligns gasoline with fuel quality standards and provides environmental, health, and vehicle benefits.